Construction is a key driver of the Australian economy, contributing around 12 per cent of GDP and employing more than 1.3 million people. Major urban centres such as Sydney, Melbourne and Brisbane are undergoing extensive residential, commercial, and infrastructure development. The rise of renewable energy projects, transport upgrades, and higher-density housing has increased the pace and complexity of construction activity.

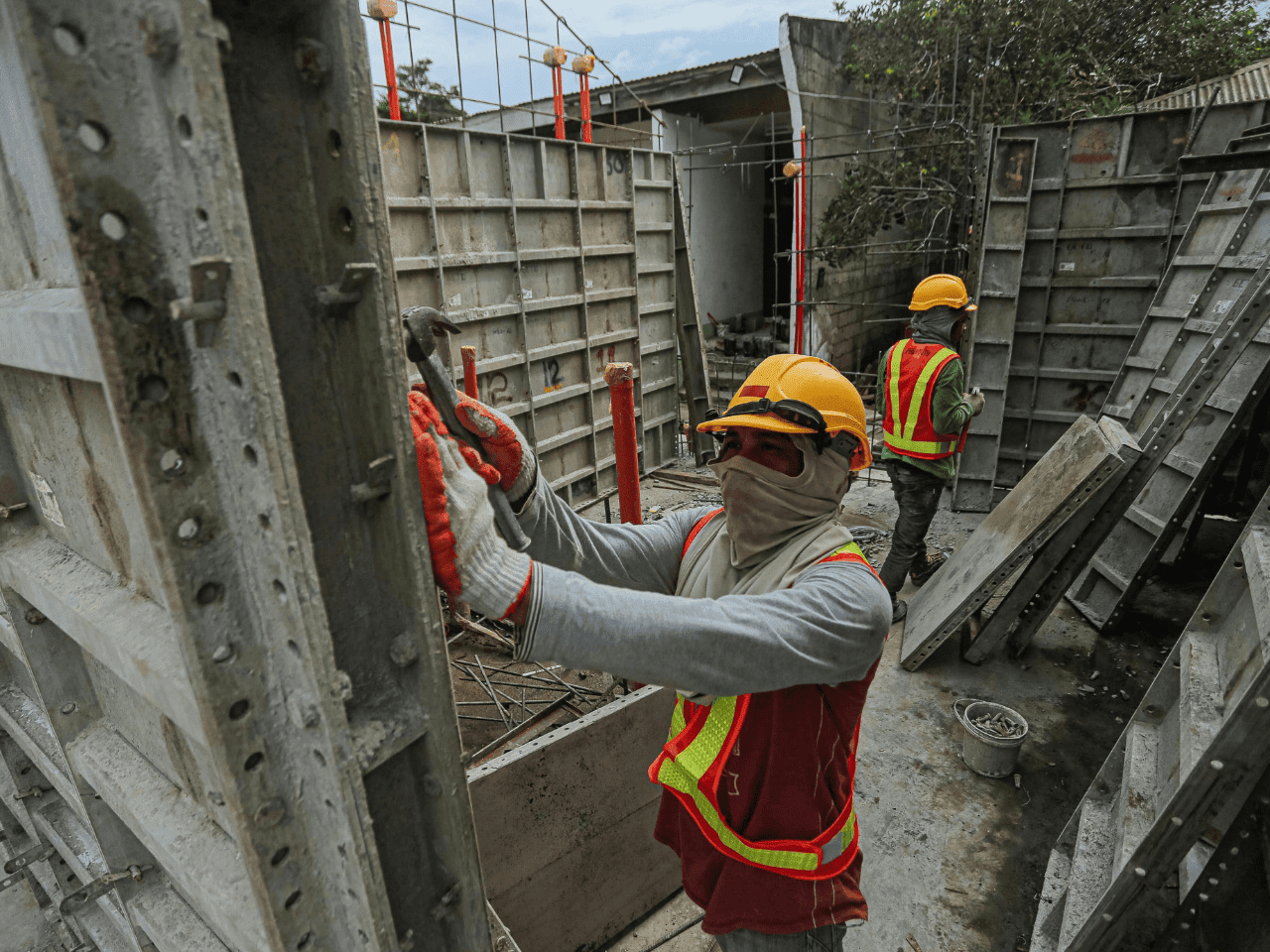

This growth amplifies supply chain challenges. Building project delays, construction safety issues, or supplier failures can ripple through projects, impacting timelines, costs, and compliance. Safe Work Australia (2025) reports that construction accounted for 20 per cent of workplace fatalities last year, with 37 deaths and more than 17,000 serious injury claims, many involving subcontractors and temporary workers.

Australian construction companies face rising pressure to deliver projects safely, sustainably and without delays. But many overlook a major vulnerability: their supply chain. A single weak supplier or poorly managed contractor can derail an entire project. Supply chain risk management is an essential component for successful construction delivery.

Companies need better systems. These systems will help manage supplier risk, track contractor performance, ensure construction site safety, and meet ESG reporting standards. Achilles helps companies build strong, transparent and compliant supply chains that perform under pressure.

Why Supply Chain Risk Management Matters

Construction relies on many moving parts. Every project depends on materials arriving on time, subcontractors meeting deadlines and everyone following construction site safety rules.

Here’s what can go wrong:

- A supplier goes bankrupt mid-project, causing delays.

- A contractor cuts corners on construction site safety, risking serious incidents.

- Your ESG compliance data falls short, putting you at odds with investors or regulators.

By managing these risks early, companies avoid major setbacks later.

Key Supply Chain Risks in Construction

1. Supplier Failures

Suppliers can collapse financially or fail to deliver what they promised. This stalls construction and adds unplanned costs. Vetting suppliers before engaging them is crucial. Ongoing checks help catch red flags early.

2. Poor Contractor Oversight

Contractors often hire subcontractors. Without clear monitoring, it’s hard to know who’s working on your site and if they follow your standards. Weak contractor management leads to quality issues, safety risks and compliance gaps.

3. Worksite Safety Failures

Unsafe practices by subcontractors can cause injuries, shutdowns or fines. Even if you didn’t directly hire them, your company is still responsible. Strong worksite safety systems must apply across all levels of the supply chain.

4. ESG Compliance Gaps

Environmental, Social and Governance (ESG) reporting is now a core business responsibility. If your supply chain includes unethical labour, unsustainable practices or poor governance, you risk reputational damage and regulatory trouble.

How Does Achilles help?

Achilles is a global leader in supplier risk management helping, businesses assess, monitor and improve their supply chains. It connects buyers with prequalified suppliers and gives them tools to track compliance, safety and sustainability indicators.

Construction companies use Achilles to:

- Pre-qualify suppliers and contractors based on strict standards.

- Monitor risk in real time.

- Onsite audits ensure worksites are compliant.

- Collect accurate data for ESG reporting.

- Improve transparency at every level of the supply chain.

Case Study: Skanska and Achilles

Global construction giant Skanska used Achilles to elevate their supply chain management. Here’s what they achieved:

- They used Achilles for supplier prequalification and collect consistent supplier data.

- They ran quarterly reports to track trends and spot risk early.

- Over three years, they reduced supplier non-compliance by 74%.

This shift from reactive to proactive management helped Skanska control costs, improve site safety and meet ESG compliance goals.

Australian construction firms can use the same tools to solve similar challenges.

Benefits for Australian Construction Companies

1. Stronger Supplier Vetting

Achilles lets you screen suppliers before you sign contracts. You can check financial stability, safety records, certifications and ESG alignment. This helps you avoid risky partnerships from the start.

2. Safer Worksites with our Ethical Business Program

Achilles helps you improve recruitment practices and working conditions across your sites. Through ethical audits and worker assessments, you can identify risks early, ensure fair labour practices, and maintain safer, more compliant worksites.

3. Simplified ESG Reporting

Achilles collects and organises ESG-related data across your supply chain. This makes it easier to produce ESG reports for regulators, investors or internal stakeholders. With everything in one place, you save time and improve accuracy.

4. Real-Time Risk Monitoring

Instead of reacting to problems, you get alerts and insights that help you act early. Achilles gives you tools to monitor performance your contractors before issues escalate.

5. Seamless Integration with your existing ERP systems

The Achilles platform seamlessly integrates with leading ERP systems to provide you a holistic supplier risk view.

Steps to Improve Supply Chain Risk Management

Step 1: Audit Your Current Supply Chain

List all suppliers. Identify contractors who are compliant and those who aren’t. Look at safety records, financial health and ESG impact. This gives you a clear starting point.

Step 2: Begin your contractor assessment

Begin your contractor assessment journey with Achilles. This standardises the process of supplier verification and filters out high-risk providers and gives visibility on your contractor’s risk profile.

Step 3: Set Non-Negotiable Standards

Make safety, compliance and ESG performance part of your contracts. All partners should know what you expect from day one.

Step 4: Monitor and Report

Track supplier performance over time. Use dashboards and reports to catch downward trends early. If a supplier starts missing deadlines or safety targets, act before it impacts your site.

Step 5: Review and Improve Continuously

Managing supply chain risks is an ongoing process. Keep reviewing your process. Use what you learn to improve vetting, safety training and ESG practices.

Why This Matters Now

Construction in Australia is under more scrutiny than ever. Employment regulations are strengthening. Environmental regulations are getting stricter. And investors want proof that companies act responsibly.

If you can’t show that your supply chain is safe, compliant and sustainable, you’re exposed to legal, financial and reputational risk.

Using a proven platform like Achilles helps you stay ahead. You get visibility, control and data to back your decisions.

Australian construction companies that invest in supply chain risk management gain a real edge. With Achilles, you can reduce supplier risk, improve contractor management, raise worksite safety and deliver stronger ESG reporting.

Next Steps

Start by reviewing your current risks. Identify and segment your suppliers based on their risk level. Begin your supply chain risk management journey.

Structured supplier prequalification, monitoring, and reporting can help reduce supplier risk, strengthen contractor oversight, and improve worksite safety.

The right tools will make this process easier. Contact us today to know more.