The Need for Supply Chain Risk Management

In today’s volatile global environment, supply chain risk management is an important component of business success. Disruptive events have revealed problems in global supply chains. Examples include the Suez Canal blockage, the Covid-19 pandemic, and ongoing geopolitical tensions. The increasing number of climate-related disasters has also highlighted these issues.

These challenges show that organizations must adopt a strong supply risk management strategy. This will help protect operations, secure revenue, and keep customers happy.

Businesses are increasingly moving away from reactive “just-in-time” models and embracing proactive “just-in-case” approaches. This shift ensures resilience even in the face of uncertainty, minimizing the risks of supply disruptions and reputational harm.

As Soren Skou, Chief Executive of AP Moller-Maersk, remarked during the Suez Canal crisis:

“How much just-in-time do you want to be? It’s great when it works, but when it doesn’t, you lose sales.”

In a competitive market, managing supply chain risk effectively can be the difference between thriving and merely surviving.

Challenges in Supply Chain Risk Management

Managing supply chain risk is complex, and organizations face several persistent challenges in their journey toward resilience:

- Insufficient and Inaccurate Supplier Data

Many companies lack comprehensive visibility into their supplier networks, making it difficult to identify and mitigate risks effectively. According to a 2023 report by Willis Towers Watson, only 12% of firms have identified all the data they need to manage supply chain risks with robust processes to gather it. - Difficulty Prioritizing Risks

Supply chains face a variety of risks, including financial instability, cyber threats, and natural disasters. Developing a supply risk management strategy that effectively prioritizes these vulnerabilities is essential. However, a 2023 survey by Interos revealed that only 5% of procurement leaders have reached a stage of continuous risk pre-emption and resilience building. - Resource Constraints

Managing extensive supplier relationships across multiple tiers and regions demands significant resources. The same Interos survey found that the average annual cost of different supply chain disruptions ranges from $43 million to $47 million, underscoring the financial impact of inadequate risk management - Dynamic and Evolving Risks

The risk landscape is continually changing due to factors like geopolitical tensions and climate change. Recent disruptions in the Red Sea from attacks by Yemeni Houthi rebels have greatly affected global shipping. Ships are now taking longer routes, which creates a ripple effect on international sea trade.

A Framework for Understanding Risks

Paul Hopkin’s “Fundamentals of Risk Management” is one of many useful models offering a practical framework to categorize and address risks.

Businesses should assess supply chain risks in the following categories:

- Financial Risks: Supplier insolvencies or credit failures.

- Geopolitical Risks: Trade restrictions, political instability, or embargoes.

- Natural Disasters: Extreme weather events exacerbated by climate change.

- Cyber Risks: Threats to digital infrastructure or operational technology.

- Compliance Risks: Evolving Environmental, Social, and Governance (ESG) standards.

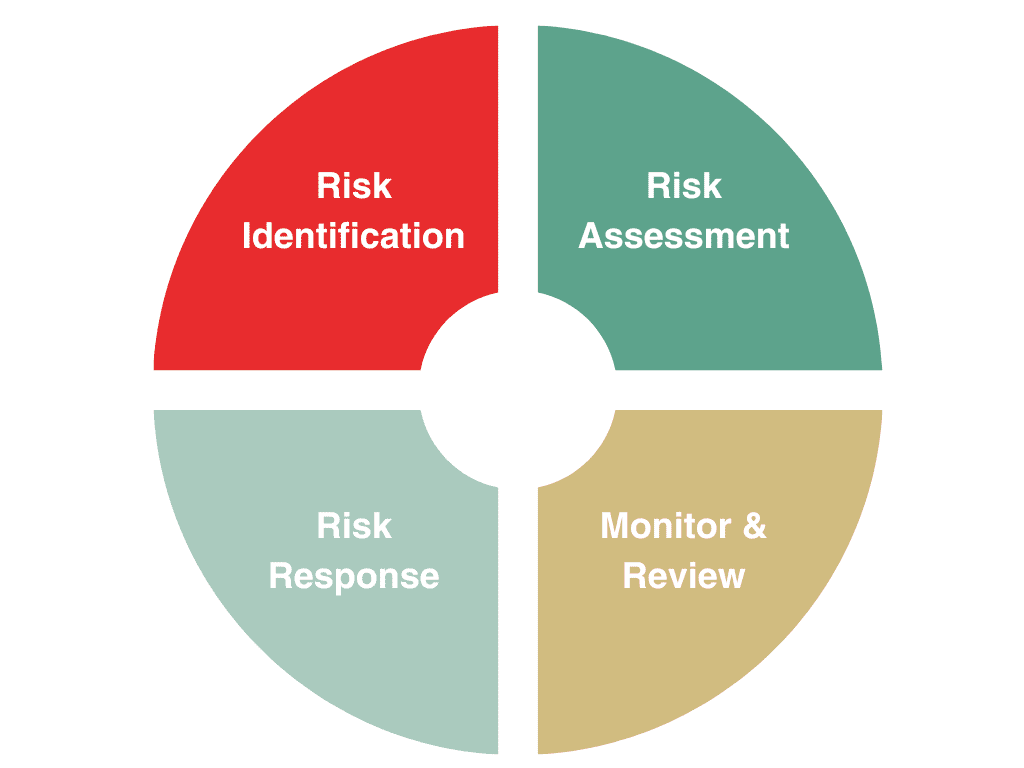

4 Steps to Manage Supply Chain Risk

Effectively managing supply chain risks requires a systematic approach. Here are four key steps organizations can take to identify, address, and monitor risks while ensuring resilience:

- Identify Risks: Achieving transparency and visibility across your supply chain is the foundation of effective risk management. Organizations must gather accurate, validated data on their suppliers to identify potential vulnerabilities. This includes understanding suppliers’ financial stability, compliance with regulatory standards, and exposure to external risks such as geopolitical issues or climate disruptions. Transparency is key to identifying risks like single points of failure, reliance on specific geographies, or ESG compliance gaps.

- Assess Risks: Prioritize risks using a risk matrix, evaluating their likelihood and potential impact. Consider single points of failure and aggregation risks, such as reliance on specific geographies or materials.

- Respond to Risks: Implement mitigation strategies based on the nature of the risks identified. These include avoidance (changing suppliers), reduction (increasing inventory), sharing (purchasing insurance), or acceptance (monitoring manageable risks).

- Monitor Risks: Risk management is ongoing. Continuously track supplier performance and external threats using analytics tools and real-time data. Adjust strategies as the risk landscape evolves.

By following these steps, organizations can develop a robust supply chain risk management plan, ensuring agility and resilience in an ever-changing global environment.

Turning Risk Management into a Competitive Advantage

In today’s unpredictable global market, a robust supply chain risk management plan is more than avoiding disruptions. It is also about building resilience and gaining a competitive edge. By achieving transparency in supplier relationships, assessing and prioritizing risks, and implementing proactive strategies, organizations can safeguard their operations and reputation.

Businesses that continuously monitor risks and adapt to new challenges are better positioned to thrive in an environment where agility is key. Investors, customers, and regulators increasingly demand robust risk management and supply chain sustainability, making these practices integral to long-term success.

Achilles provides the tools and expertise to support this journey, offering pre qualified supplier data, supply chain risk management, and compliance solutions. Partnering with Achilles enables organizations to transform their supply chain risks into opportunities for growth and resilience.

Take the first step toward building a stronger, more resilient supply chain today with Achilles.