Doing things differently is an idea that gets a lot of airtime in the maritime industry. Sometimes the ambition falls short of the reality as intensely commercial business models make demands that organisations struggle to achieve.

But from time to time it does happen, not by chance, but as a result of being prepared to align objectives in such a way that creates value and generates shared benefits.

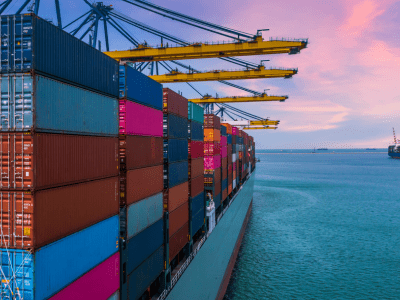

Sea Sourcing was founded in 2022 by Seaspan and Anglo-Eastern with just this type of agenda; to create a partnership between the buyers and suppliers. ONESEA, a joint venture between Seaspan and Ocean Network Express (ONE), later joined as a member of Sea Sourcing.

“From the start we were determined not to be just another consolidator, but to provide a genuine in-house procurement function, explains Managing Director Gareth Hartlett, who brought multi-sector experience in shipping and procurement to Sea Sourcing. “We wanted to approach it differently, to create a unique combination that could consolidate volumes but with a strong ESG perspective.”

The partners also believed this could help bring scale to their suppliers, enabling them to grow their business, rather than focussing simply on volume and price. This meant extending the development time by several months against an increasingly volatile macro-economic picture which increased the pressure to make contracts fit for purpose.

“Naturally we wanted best value but when you are bringing circa 1,000 ships to the programme you can take a longer-term view with some stable principles.

Sea Sourcing began its audit process with desktop exercises but immediately found shortcomings in terms of differentiation between vendors and a lack of granularity and segregation between the companies themselves. Having a conversation that could yield more intelligence was also an obstacle. “It just felt too binary to be useful,” adds Hartlett.

Suppliers could self-validate but didn’t have to prove it, leading Sea Sourcing towards the more robust Achilles approach which could improve reporting but also drive increased collaboration.

Using the Achilles platform enabled Sea Sourcing to engage with suppliers and establish their level of performance and wider strategy. The availability of more data enabled Sea Sourcing to understand what actions the supplier was taking, where they were headed and critically have that information validated.

“For us it’s about being a good corporate citizen and the importance of improvement. It’s part of everybody’s job – we are all responsible, whether it’s making relatively quick improvements or creating bigger opportunities.”

Part of the motivation is in making such improvements a P&L item so the effect can be measured. SeaSourcing is committed to reducing plastic waste, so suppliers are motivated to remove that from their offers. “Do that and it becomes situational; you can take a more measured approach,” he says.

Audits include validating shipyards used for repairs and maintenance to check for working practices, indentured workers or those from sanctioned counties, as well as vetting that can establish the ultimate beneficial owner.

“Using Achilles, we can perform an agreed number of audits per year and add more if we need to. The choice of who we audit is up to us, not the vendor and Achilles can perform the audit on our behalf,” he explains.

Carbon emissions have a key role to play in reporting. Hartlett says most vendors were aware of the increased pressure to account for scope three emissions and some were already tracking them, though the degree of detail would naturally vary by location and size of the operation.

“We have marine chandlers that have definitely been on a journey with us. It’s just wrong to treat your supply chain like everyone is a Tier one global operator and expect the same performance,” he says. “It’s not correct to expect the same outcomes or focus areas of suppliers across a global footprint.”

Anglo Eastern and Seaspan also go through the Achilles auditing process. “You have to put your money where your mouth is, to demonstrate to our suppliers that we hold ourselves to the same standards we ask of them and because we have stakeholders who look for it in our ESG reports.”

As a major tonnage provider to container lines, Hartlett says Seaspan’s customers have a vested interest supply chain transparency and the same is true for Anglo-Eastern’s ship management customers. “They are reading it, noting what we are doing and how that fits into their overall objectives and ambitions.”

The notion that ESG has slipped down the list of boardroom objectives appears less accurate than a skim of the headlines might suggest. He thinks that suppliers are increasingly interested in ESG when they can see commonalities that can help drive sustainability objectives.

He says the response from vendors to the Achilles system has been positive, with some vendors already familiar with the process and others keen to understand the cost structure versus the benefits.

“There might be some who might be concerned they won’t live up to the standards, but we also have to make relevant to who they are; it needs to be fit for purpose,” he says. “We started with our top one hundred suppliers and moved into the next one hundred. Our plan is to make it part of tender so that in future [not being audited] will be an eliminating factor. It will have more and more weight on how we make decisions.”

In fact, the response is already apparent; he cites two vendors that have transitioned from the bottom performance quartile to the top, improvement that is tracked in monthly board meetings.

By using the expertise in Achilles to create the challenge – to itself and its suppliers – SeaSourcing has enabled more boats to rise, creating standards that can be understood and applied with flexibility. “We knew what we wanted to see and how to assess with empirical data what good looks like,” he concludes. “We all have opinions; this is about what you can do when you start to assemble real data points.”