They’ll Fill It In, Right?

Accurate supply chain reporting has become a core requirement for organisations operating in increasingly complex markets. Regulatory changes, investor expectations and ESG reporting standards mean that supply chain data must be reliable, current and comprehensive. However, four common myths continue to hold organisations back.

Myth 1: Supply chain data will be ready when you need it

Assuming that supplier information will be complete and ready for reporting without active management is a mistake. Research by McKinsey found that just 2% of companies have visibility into their entire supply chain beyond the second tier, making blind spots a common risk.

Structured supply chain data management processes are needed to ensure information is up to date. This means setting clear reporting requirements for suppliers, tracking submission rates and validating data before it is used in ESG reporting or performance analysis.

Myth 2: Sustainability reporting tools automatically ensure accurate reporting

The use of sustainability reporting tools and ESG platforms is growing. However, their value depends on how well they are integrated into procurement and supply chain management processes. A 2024 Reuters Events survey found that many organisations investing in ESG software still report challenges with effectiveness and ease of use (Reuters).

To make these tools effective, they must be aligned with data collection processes in procurement. Supplier onboarding, contract management and performance reviews should feed directly into the system, reducing manual work and improving the accuracy of supply chain reporting.

Myth 3: Procurement operates separately from ESG reporting

Procurement teams are central to the quality of ESG disclosures. The data they collect during supplier selection and ongoing management forms the basis of sustainability metrics. Deloitte highlights the importance of coordination between procurement, finance and IT in meeting new reporting requirements.

By embedding ESG requirements into procurement processes, organisations can improve the completeness of supply chain data and ensure reporting deadlines are met. This integration also supports wider objectives such as risk reduction and supply chain visibility.

Myth 4: Supply chain analytics are only relevant to operational performance

Supply chain analytics are often associated with cost management and delivery performance. Increasingly, these analytics are also used to track ESG compliance, carbon emissions and ethical sourcing. Advanced analytics tools can link supply chain visibility with environmental and social performance indicators, providing a more complete view of supplier impact.

When property management procurement teams use analytics alongside sustainability reporting tools, they can identify underperforming suppliers, address risks earlier and demonstrate progress against ESG goals.

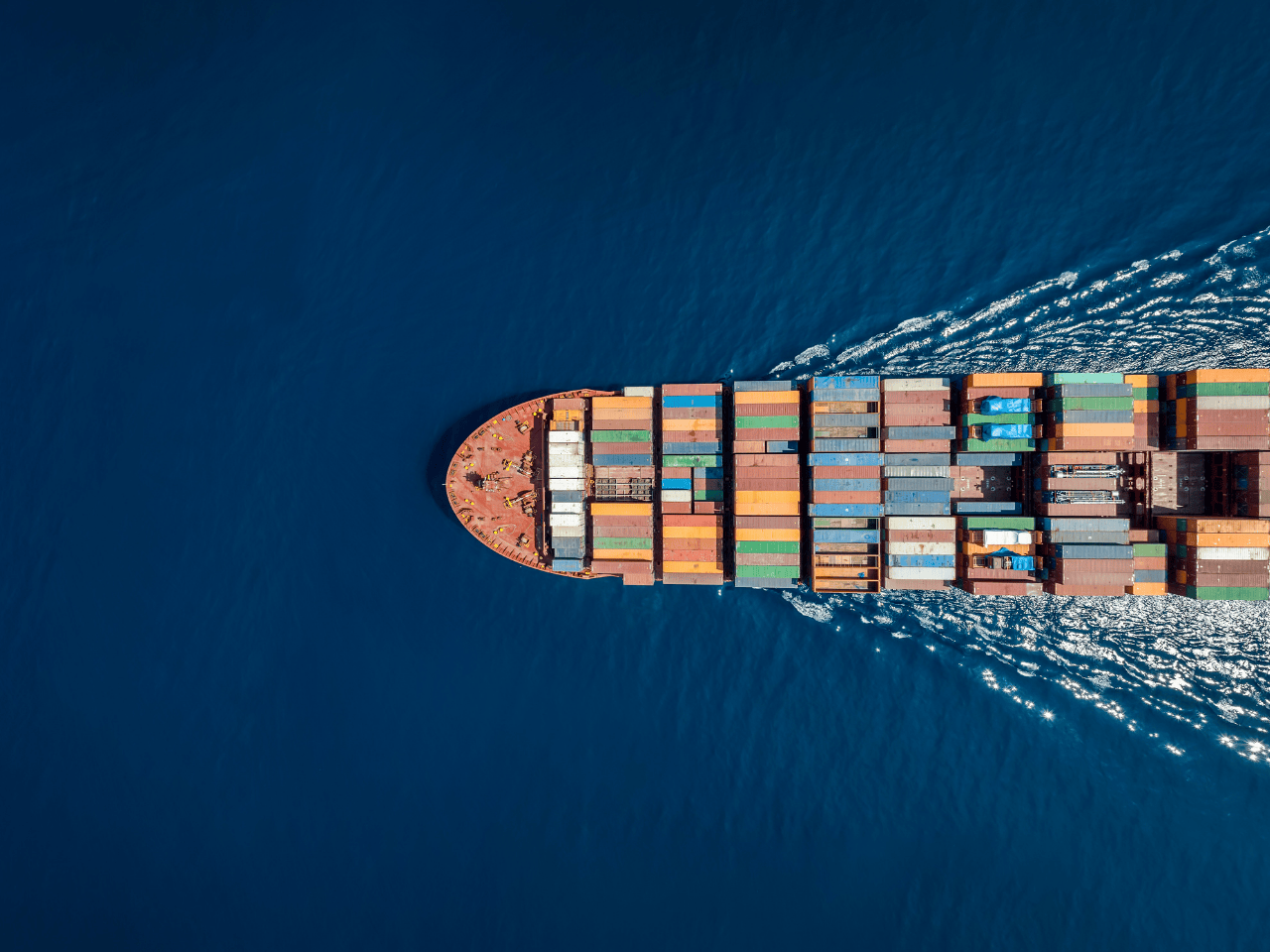

Why addressing these myths matters

Clear, accurate supply chain reporting supports more than compliance. It enables better decision-making, improves resilience in supply chains and supports corporate commitments to responsible business. Reliable supply chain visibility reduces the likelihood of disruption, strengthens relationships with stakeholders and helps meet global sustainability targets.

Breaking away from these myths helps organisations improve reporting accuracy, reduce compliance risk, and strengthen stakeholder trust. In the UK, this is particularly important as requirements expand under SECR, the Task Force on Climate-related Financial Disclosures (TCFD) framework, and public sector expectations under the Procurement Act 2023.

Strong supply chain visibility not only supports compliance but also improves resilience, reduces social and environmental risks, and enables organisations to meet wider sustainability commitments.

Practical steps to improve supply chain reporting

1.Assess current supply chain data

Identify gaps in supplier information and determine which data is critical for reporting, compliance and risk management.

2.Integrate tools with procurement

Ensure sustainability reporting tools connect directly to procurement processes and supplier databases.

3.Set clear supplier expectations

Communicate reporting requirements, deadlines and verification processes to suppliers at the outset of relationships.

4. Use analytics for insight

Apply supply chain analytics to monitor both operational and ESG performance.

5. Collaborate across departments

Bring together procurement, sustainability, compliance and IT teams to maintain a single, reliable source of supply chain data.

Addressing these myths requires a focus on processes, integration and collaboration. By improving supply chain data management, linking procurement to reporting requirements and making better use of analytics procurement professionals can deliver supply chain reporting that meets both organisational needs and external expectations.